Heathkit SB-401 Amateur Transmitter

Click here to jump to the latest post.

Radio Electronics Magazine (advertisement - page 69)

December - 1966

Kit Price...............$285.00

Assembled: N/A

Weight: 34 pounds

First Shipments: September - 1966

Introducing the new deluxe SB-401 transmitter for 1966!

This was an upgrade from the older SB-400 and paired with the SB-300 receiver at the time. It was capable of stand-alone transmit operation or in transceiver mode paired with the receiver. Many amateur operators would buy the new transmitter and pair it with their older SB-300 receiver. Heathkits' assembly manual showed a diagram of how this was done with clear hookup diagrams.

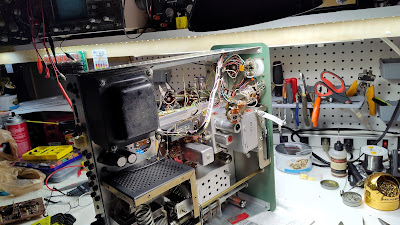

Dad's unit was bought used but wasn't working well. He did some work to it to get it right and used it for many years. It has survived a few flooded basements worth of very high humidity, without being submerged. The paint is failing and flaking away as is happening to the SB-303 (solid state receiver) he purchased with this unit. They will have to be stripped completely and repainted.

As for the electronics I already spotted the load select drive string and spring are missing. It's not inside the chassis anywhere so it disappeared at some point. There's also a break in a connection point in the final so there's going to be a few surprises as I dig into it.

_______________________

February 14, 2021

Now for a recap, I did purchase a working set over twenty years ago but never put it into service as life got in the way. Things happen and life throws you curves and you wind up in the weeds out in a field trying to get back to where you were. The SB-301 in the set I bought was brought back to life and works. It was horribly contaminated with cigarette smoke, tar and nicotine. The chassis was stripped down and put through a wash and baked dry. The case was already flaking paint everywhere and was treated a few times with Aircraft Stripper. This paint is so tough I almost half thought it was epoxy type but no. It's just thick in places and really hard to get off without sanding. Sanding will take off metal and I don't want to do that.

The SB-401 in my set is the donor plain and simple. Still contaminated, it will offer all the parts I should need to bring the one my dad gave me back to life. Even the load set drive string and spring.

So that should get you up to date on what's going in the shack. So hoping to have this complete by Christmas. All the electrolytic capacitors will be replaced no ifs, and's, or buts. From the preliminary evaluation there aren't any wax/paper capacitors nor bumblebee's or paper-in-oil types. Just ceramic and maybe a few Mica types along with the electrolytics. All of the carbon composition resistors should be replaced but I'll get the unit recapped and begin the testing evaluation with the dim bulb addition to the isolation transformer and a variac to bring it all up slowly. Hopeful is the word that comes to mind.

That's it for this update. Thanks for stopping by!

Bye for now!

___________________________________

|

It's a bit dirty after sitting in a box for so long.

With the exception of the missing dial string

everything appears to be there. |

|

The Final. Missing covers so the donor will

donate. |

|

| Missing string between these pulleys. |

|

He never had the crystals in this since they

were in the receiver. They were connected

in transceiver configuration using the

SB-303 as the VFO to the transmitter. |

|

| Clean under here. |

_____________________

February 24, 2021

Woot! Got my capacitors in from Mouser today and got started on the SB-401 transmitter. After the evaluation these two were the hardest to change out because they are located on the backside of the terminal strip board. A little instruction to show the wires they should stretch before doing anything strenuous allowed me to move them just enough to rotate the board and get the electrolytics out. The newer, smaller ones installed very easy. The others look to be pretty easy. Still haven't decided on what to do about the two big filter capacitors yet. Restuff them with the new parts or just leave them exposed? Since I'm replacing these only to electrically test the transmitter to see how much repair is needed, I'm not worried about replacing the big filter capacitors with modern ones leaving them exposed for testing. Wish me luck!

__________________

February 28, 2021

Greetings!

Tonight I was able to get a little bit of work done on the transmitter. Another electrolytic capacitor. this time, it's a dual section 100/40uF 350V/300V can type. I opted for discreet components as I'm still evaluating the unit. Replacement of all of the electrolytic capacitors is precautionary so that a more thorough testing can be done to evaluate any issues.

This capacitor is #25-59 at AE in the manual. The replacement pieces are a 100uF 450V by Nichicon and a 47uF 500V by Nichicon to replace the 40uF 300V section. I probably could have gotten a 40uF but Mouser and Digikey at the time did not show any in stock. Both parts are rated 105 degrees Celsius.

To get to the lower terminal for the 40uF section, the transformer needed to be moved out of the way. The nut driver would not fit over two of the nuts that are jammed up against the chassis. The screws running through the transformer's core plates would not budge so loosening the nuts required access to them. The nuts were loosened to be flush with the end of the screw to lower it enough to get to the capacitor's terminals more easily. Allowing it to remain attached was a plus as disconnecting all of the wires would be troublesome.

|

| #25-59 at AE |

|

The transformer was lowered in the space to clear

the terminals. |

|

Removed the phenolic disc from the old cap.

|

|

| Mounted new caps onto the old disc. |

|

Soldered the leads to the terminals. The ground

lead of the terminals were soldered to the twist

lugs. Then the twist lugs soldered to the plate. |

|

It's back together. The rectifier tested good as

did the 2 watt 110K ohm carbon comp resistor. |

|

| How it looks after reassembly. |

I really wanted to restuff the can but this is for evaluation. If things work out I may use the can from the donor to make a "proper" era correct looking can capacitor.

I might just heat up the old can from this just to get it emptied out. Some aluminium foil on the cookie sheet and let the tar ooze out at 450F in the recently acquired bench oven.

So that's it for today. I know it isn't much work done but I have my reasons. The next capacitor to be replaced will be...

|

...this one. Then I can turn the radio up on its

side and begin working on the top side caps. |

TTFN!

______________________________

March 2, 2021

Good Evening!

Tonight's short work session replaced the 100uF 200V electrolytic cap between terminal strip K, Lug 1 and L, Lug 4 with the positive (+) lead at Lug 4. This was replaced with a 100uF 250V from Nichicon. I installed the cap with the (+) lead as short as possible. The (-) lead was fitted with a length of heat shrink tubing just in case since this connects directly to RED-YEL lead from the transformer.

|

| Before |

|

| After |

Getting this one replaced was easily done but the next two were a bit more involved.

There were two .005uF Z5U disc capacitors that back in the day were considered a safety capacitor. However, these typically would fail-short and cause all kinds of unpredictable results. The predictable one was fire but you couldn't tell if it would at the time of the failure. The idea was when this rig was designed, most homes did NOT have a grounded wall outlet as we do today. Instead you were expected to ground the chassis to a water pipe ground since plastics like PVC and PEX water lines weren't used in new construction let alone all the homes built prior to Heathkit's release of this unit in 1966. Sooooo, one of the capacitors would fail and hopefully open the circuit preventing damage to the rig. But wait! The capacitors were connected from Line to Ground and Neutral to Ground so how could the rig not be damaged? Failing short gave the fuse job of protecting the equipment...in the fuse box...somewhere else in the house. The rig had no fuse of its own and the switch might not cut the power to a shorted transformer on the primary side. You had, after all, a 50/50 chance the Line or Hot side of the house current was connected to the lead with the switch. Polarized plugs had been available since 1912 but was largely ignored until a mandate was issued for safety for most devices and appliances. Even today polarized plugs, as common as they are, are not required on double-insulated devices. You'll see them mostly on power tools with two prong cords and such like drills and saws made with plastic bodies and handles. Things take time and eventually all AC plug in devices will use polarized plugs. Ideally, something like the V style plug in some parts of the world prevent you from plugging in the device in any other way but one. Newer designs NOT OF NORTH AMERICA even prevent power to the device unless it keys an interlock between the plug and outlet.

I may not equip this transmitter with a grounded plug since the wing nut in the chassis was intended to be the grounding point for the closest ground rod. Using a ground cord would get the chassis grounded but not to the closest point. It would run about 80 feet to the circuit breaker box then backtrack to the utilities meter and grounding rod, which happens to be outside my window about 15 feet from the bench through the floor and out to the rod. Grounding through the plug AND from the wing nut to the grounding rod would create a ground loop and other nasty issues will crop up like hum and Common Mode Current.

Back to the "safety" caps...

I replaced them with X1Y2 type safety capacitors rated for Line to Ground, Neutral to Ground, and Line to Neutral. Transients would be suppressed and if they fail, they fail open. These are an advanced design of Metal Oxide Varistor (MOV). They are at location BC, BD, BE in the manual.

|

| After. I forgot to get the before shot. |

That's it for now. Hopefully will have some time later this week to get to the Carrier Generator Circuit Board. There are several located on that one.

73

__________________________________

March 8, 2021

I was able to get a couple things done the last few days. After replacing the X1/Y2 safety capacitors I replaced the next one on Sunday.

This one right here. Now I already bought the ones I needed but didn't look at the "x-ray" drawings later in the assembly manual. Turns out this particular capacitor's leads are wide-spaced to the edge. Trying to find the second lead proved confusing until I consulted the manual. Since the radial capacitor I got doesn't have the width I wanted, I'll make do.

Not my best photo but you can clearly see the silkscreen outline of the original capacitor location and the extended negative lead bent out from under it. I could have drilled a new hole to match where the negative lead would naturally go but I chose not to. It's really dirty inside and I'm only doing this to get it back into a safer electrical condition for testing with power applied.

I also replaced the big 125uF filter capacitors which wasn't as easy as I first thought.

|

Kind of hard to see but both new capacitors occupy the space of one

of the originals. The terminal strip was folded down toward the new

pair. I had to extend the 500K 1% resistor to reach the lead. |

|

| Top View |

|

| I forgot to turn the camera sideways. |

Now a rule of thumb in electronics is to make the "more positive potential" lead of a component as short as practical to lower the chance of inducing or picking up EMI/RFI into that circuit. This was why capacitors like film types were marked with a line, dot, or text stating "outer foil side". This lead was to be connected to the lower potential and shielded the higher potential in the circuit. Most modern film type capacitors like Polyethylene or Polypropylene are made in such a way so as to not care which lead is the outer foil side lead. Still, I have found many of the current production Orange Drop capacitors aren't made this way and knowing which lead is connected to the outer foil is important, especially in amplifier stages. So I use my oscilloscope to find which lead it is. They have a line or dot on them but that doesn't correspond to the foil side lead all the time. It's just part of the printing on the casing and means nothing until it's tested. Once tested I put a dot on the end of the capacitor to make it easier to identify.

Mr. Carlson's Lab on YouTube has demonstrated this and built a device to make it easier to detect which lead is which. The plans and information are on his Patreon account along with over 90 videos with design information and projects to build yourself in a kind of "on the job training" experience. You watch the videos that explain the device and the circuit(s) and build his projects to gain experience in doing the work rather than sitting in a course reading and working out theory all the time. I've learned a lot from his videos and I hope you give him a chance to learn from him.

That's it for tonight. All of the capacitors are done! Now it's time to get to the Carrier Board and replace all those little ones.

TTFN!

________________________________

April 1, 2021

The transmitter work is slowly coming along. Tonight I did the resistance check and found two things. First, many of the test points are testing at much higher values than should be considered within normal. Second, I heard a "pop" from my VTVM and it won't read accurately. So guess what? I get to repair it <sigh>. That will have to take precedence since I need it's 11M ohm input impedance to do the rest of the testing unless I can make a probe for my DMM and get the same accuracy. I believe it only has a 10M ohm impedance so adding a 1M ohm resistor to a probe should satisfy the requirement. Now where did I put that coaxial probe cable?

________________________________

October 16, 2021

It has been a while since I worked on this transmitter. Admittedly I had an ongoing Jeep project since 2017 that was nearing a deadline. I needed to focus on that to enjoy my vacation time this year.

Now that I did get to enjoy the vacation, short as it was, I have cleaned the bench off and restored it to service again. The radio interests can now be the focus and this transmitter will be made operational. But not right away. After some more resistance checks I was finding more and more resistors were waaaaay out of spec. I'm speculating these have all absorbed moisture over the years of the North Carolina humidity and contaminated the carbon slurry inside the casings. This usually happens at the juncture of the lead and case. Without a tight seal, moisture will find it's way inside. The big 1 and 2 watt components are still within spec. I will replace these anyway. All others have to be replaced since more than half of the 100 resistors in the transmitter are more than 10% above rated value. I'm sure they can be used in other projects as long as the leads are intact and the cases aren't damaged from the removal and handling.

Just Radios has a kit of post-WWII resistor values that I will need. The kit contains 20 each of all of the values. Some I won't need and others will need 7 or 9 of them. These are all 1 watt resistors. The 2 watt parts will need to come from Mouser or Digikey. Or maybe even Surplus Sales of Nebraska. Hard to say right now. It's late so I'm not going to look now.

Suffice it to post tonight I want to get this up and running for Christmas so it will require parts and large portion of free time to accomplish this. Wish me luck!

______________________________________

October 17, 2021

I just completed ordering the entire resistor list. Just Radios had most of them in Carbon Film rated at 500V. A few of the oddball values had to be ordered through Mouser. Those were the 10, 68, 750, 8200, 500K, and 4.9Mohm values. Actually the 4.9Mohm wasn't even available so I had to opt for the 4.99Mohm part. The 500Kohm was the only precision resistor in the whole device. I was able to get a Metal Film 1% 25PPM from Mouser by Ohmite. I also purchased a new 4Kohm wirewound 10W resistor to replace the 7W part. It looks like the ceramics are crumbling so best to have the new part on hand. Most of these from Mouser were by Ohmite. The others were Vishay/Dale and Vishay/BC. The 33K 2W resistor is a Vishay/BC Metal Film type. The other two, a 10K 2W and three 100K 2W parts are carbon film. I don't think there will be an issue with the forgiving nature of tube equipment. All parts are 5% tolerance, 500V parts except the wirewound rated at 1kV.

Building the list wasn't hard. The replacement list has everything I needed to know. The problem I found was getting some of those values that weren't included in the kit. Just Radios has a large selection but didn't have the low value carbon film type below 100ohms. They did have them in Metal Oxide and Metal Film but neither were rated 500V operating. It's all good though. When they re-open my order will ship out on the 22nd. I should have the parts from Mouser by then.

Well, that's my update on this. Back to strategizing the replacement of the parts. It would be easier to replace them if the circuit boards were out of the chassis but there are so many fragile coax connections I will attempt the swaps in-chassis.

___________________________________

October 25, 2021

Man, oh man! I just received the last package of parts needed to get the SB-401 rebuild started! I purchased a carbon film resistor kit (post WWII) for most of the values I need. Most of the resistors are 1/2 watt but for the same price, and headroom due to the heat some of these things are exposed to, I opted for the 1 watt kit. 2 watt originals will be replaced with 2 watt carbon or metal film types. The one 7 watt wire wound (ww) resistor will be upgraded to a 10 watt. As mentioned before, the ceramic on the 7 watt is starting to flake and crumble a bit or it's the epoxy encasing the element. Either way I'd rather not risk damage to the rig.

Some values weren't available from Just Radios in carbon film. Those are as follows: 10, 68, 750, 4k(ww), 8.2k, 10k(2W), 33K(2W metal film), 100K(2W), 500K(metal film 1% Tol.), and the 4.9M (4.99M metal film 1% 1.5W).

As you can see not all of the resistors I wanted were available in carbon film. I probably could track down some and hope none had been compromised by time or environment. I played it safe and took the metal film over the metal oxide for the 500V working voltage rating. The metal oxide was only rated to 350V. True 500V isn't in every circuit in the transmitter but it does allow me to use these anywhere in the rig without worrying about the voltage rating when it does matter.

So now it's time to do the Sort-N-Stash to put them where they belong before I start taking the 401 apart.

I have been evaluating how to go about the rebuild. Most repair people say to leave what isn't out of tolerance and replace only what is. Others take the shotgun approach to parts replacement but stick with the original values. Don't mix components unless absolutely required to to get an exact duplicate of an original value when currently unavailable. I agree with that last part. However, going about repairing this transmitter is a kind of revolving door. Change one bad part and several others no longer allow the circuit to be aligned. A poly cap in place of a paper cap works beautifully, most of the time. Audiophiles know what I mean.

So I'm not keen on removing the circuit boards. The small coaxial cables have leads that are fragile to downright broken, true, but if they aren't bad, why disturb them. Working around wires that a board bonded is a challenge. Doing it will inevitably put you in a position of melting original wire insulation. Believe me, you know you did but only after you smell it. They you try to find it and discover it's burned away really fast. Yet another wire to insulate after disconnecting it anyway for that issue.

The better way, albeit a less labor intensive way is to measure the resistors properly and evaluate their role in the circuit. If they are out by more than rated tolerance, it should go. If all of them are out of tolerance, then the board comes out to minimize damage to surrounding cables/wires, and other components. This will be my approach. I've evaluated all of the 1/2 watt resistors on the two terminal strips and all are more than 12% above tolerances. These are all 5% carbon composition resistors. They have absorbed a bit of moisture. I've found two Brown Dip caps with cracked casings. One with a broken lead so those will go and be replaced with Orange Drop poly caps. So far I'm looking at complete replacement of all resistors if they keep testing out of tolerance as they have been. I found two 1 watt resistors that are still in tolerance but just barely. And the aforementioned WW resistor with crumbling epoxy or ceramic casing.

So that's it for this update. I hope to have better news next time. TTFN!

___________________

November 5, 2021

Greetings! With all of the resistors in their storage drawers I started disassembly of the transmitter on the 3rd. As I got into it and pulled the first resistor I had a sudden realization of what it was going to take to replace all the bad resistors (about 70%). The interconnects for the circuit boards seemed numerous and a few very difficult ones to get to. So I put the soldering iron down, powered it off and started rethinking the process through.

|

And so the first component was to be removed. And it was removed.

And the man rejoiced at the start of his journey. But his joy was

short lived. |

Few things really bother me. The plan to replace some of the resistors was very present in my mind and as stated before, the more I found to be way out of tolerance the more I began to deny the need to remove the boards. It's counter to the original plan and I find change difficult but faced with facts, I tried to prevent the need and it just wasn't going to happen. And that bothered me.

So while at work I spent the next day and a half thinking about the solution, not the problem. I already knew the problem. I just needed to focus on what was needed to move forward with the project. I figured out the initial steps needed to remove the boards. The Mixer board was easiest but wasn't in the way so I began with the Carrier Generator/VOX control board. This one seemed to be the most difficult with so much assembly having been done after the board was originally installed. Disconnecting and removing rotary switches just wasn't going to happen unless it absolutely had to be removed to get to a critical part. The Mode switch had to be pulled from the front panel but there was enough slack in the wiring I could kind of roll it out of the way a little. Of all the things, one screw holding the board in place was the reason for this. It also happened to be holding the dial lamp in place. I hope I can find another point to attach this. I don't relish the thought of having to disassemble the dial mechanism. The SB-301's dial mechanism still isn't right but it does work. Quite difficult. This dial works fine and I don't want to mess that up. I do have a parts donor if need be.

Now the project has gotten moving along pretty well. I'm happy to report both boards have been removed successfully. Work can begin on them this weekend. I can also clean them up good now that they are out.

Once the carrier board was out I had the mixer board out.

|

| Weird to see it in this state. |

|

Mixer board - Top

Carrier board - Bottom |

The chassis has been put aside out of the way. I do need to clean it as well and as I rework these boards I'll come up with a way to get that done.

That's it for tonight's update. Have a great weekend!

_____________________________

November 6, 2021

After getting a few things done I had time to work on the transmitter today. I chose the Mixer/Bandpass board to get reworked. I shot video of the whole reassembly process and since I rarely do videos, wasn't surprised this one didn't come out very well. I went through it again to edit but I couldn't really decide what to remove and what to keep. I may just make it a time lapse. The video length was about and hour and a half since I was trying to narrate as I worked on it. I didn't show the teardown and cleanup of the board, just the reassembly.

Moving on, the teardown wasn't anything special. The 21MHz trap and the ceramic capacitors had to be careful around. I have several Z5U .01uF ceramic disc capacitors rated 1kV in stock. However their degree of error was actually higher than the originals. The originals also have a green marking on the top edge must signify something. I haven't found what that marking means but since these don't appear to be NP0 types so I'm not too worried about it.

|

| This is what I started with. |

|

| The new 5% 1W carbon film resistors are picked and ready. |

|

| Time to reassemble it. |

One thing to note is the silkscreen on the circuit board. 91% rubbing alcohol will take it off! I got a little aggressive and it started coming off so I went back to cotton swabbing the areas. I just don't like the streaks they leave behind and tried to use a towel instead. Mmmm, yeah. Don't do that.

You'll probably notice the Bandpass Coupler wasn't removed. I only reheated the solder points for my own sanity.

The assembly went like this: Install resistors, solder them in place. Install mica capacitors and solder in place. Install the small ceramic disc capacitors and solder them in place. Install the remaining the disc capacitors and solder in place. Install the 21MHz trap and solder in place.

All of the tube socket pins were desoldered then new solder applied. Only thing left is to clean up the rosin residue.

I didn't get any stills of the reassembly as I was filming. After I was done I realized I still had an old Samsung J7 Crown phone that took good pictures. I'll charge it up and use it for future videos and stills. I would like a better holder than this...

Though the IM-4120 probably doesn't mind, it's not the best solution. The weight of the phone with too much vibration of the shelf causes it to begin to droop.

As for the Carrier Generator board, I'll work on that next. Once done it's on to the chassis mounted resistors. I can't say when this will be completed and operating but my goal in January. I have all the parts. It's just a matter of available time. You'll notice the previously replaced electrolytic capacitors featured near the top of the blog. At the time I was really hoping the resistor checks would pass but as I got deeper into the checks it was looking more and more like replacements were needed. That was back in February. I put the project away to work on the Jeep and a few other things over the Summer which is why I'm getting to work on this now. The parts were acquired and the time indoors will increase too.

Click on the image to enlarge it. You'll see I've dusted it off but other than that isn't in too bad a shape. The board can be split into two on the schematic. The left half is the VOX/Anti-VOX and Tone control. The right half is the carrier generator. The long, thin part adjacent to socket V13 is the P.E.C. Network. It's shown on the schematic as this:

This part is obviously no longer available but at least one could be built if this does fail. I read in a technical bulletin from a compilation of them by Heathkit and found they had referenced another part to replace this with. Similar to be sure but now even more rare.

This is turning out to be a pretty good project so far.

That's all for now!

_____________________________

December 18, 2021

I was finally able to get some work done on the RF Generator Board this month. Removal of the old resistors went fine but not without its troubles. The desoldering gun kept clogging up as did the SoldaPult. Still, all the parts came off well. After removing a few of the capacitors I checked the Germanium diodes and all checked out. The single poly type capacitor also checked good on the IT-28 checker and the ESR meter. It's rated @ .2uF 200V. I think it's the only one or two that aren't damaged. One other has a broken casing at the lead and another is cracked.

After removing the resistors I spent some time cleaning up the board and clearing out any through-holes as well as the cable/wire tie-in pins used as board interconnects for items from around the chassis. The board did clean up ok but lost the silkscreen for the poly capacitor mostly. The outer foil identifier was still visible but only just.

New 1W resistors were installed and fit pretty good at their minimum lead spread. The 1.5 Megohm (not megaohm) resistors were 2W metal film types due to availability of the carbon film types. Just couldn't get them. These didn't fit very well and the leads were bent around and under to the proper spacing to fit the through-hole spacing. I'm hoping this won't significantly alter the capacitance of the circuit. All resistors were set slightly above the PC board to improve air circulation around them. This isn't a "trick" of the trade but rather a preventative measure to keep the old phenolic board cooler as well as the resistors. A few of the old resistors left darker spots under them so raising the new ones off the surface will help the board stay cooler.

After reinstalling the components I sprayed the solder side of the board down with electronic cleaner and a brush to get the rosin cleaned off. This is important as the rosin can become a very high resistance bridge across circuit traces so it too becomes a preventative measure against future issues.

Since I was not able to test any of the Compactron tubes I will put the originals back in. Two of the donor tubes had equalized so they're no good. Other than this there is nothing left but to reinstall the board. It was a pain to get out without taking everything off above it so it'll be a challenge to put it back.

|

The really bad one. Looks like it may have taken

a hit getting it out of the case or maybe when I

was trying to find a place for my fingers to keep

from dropping it. Either way it's a goner. |

|

| What it looked like getting it out. |

|

| It's out but getting it back in? Now that's hard. |

|

| The first removal. |

|

| Finished |

Next on the list will be the chassis mounted components like in the first photo. These are mounted on terminal strips in classic point-to-point wiring. I can remove the chassis support rail but that's about it. Components up against a bulkhead will be more difficult to R&R.

That's all I have for this update. I will try to post closer to the end of a work session than two weeks.

_______________________

April 15, 2022

Unfortunately, there is no progress as yet. Other things are getting behind and I'm getting overwhelmed a bit. I have acquired a Hallicrafters S-120 with a loud hum (filter caps) and a Simpson Model 464 digital multimeter. The meter works on DC readings but does not in AC mode. Otherwise it just needs a calibration and it'll become my main digital bench meter.

Previously I acquired a Heil microphone arm, without base, that I was going to mount my handheld DMM to so I could move it around above the bench area as needed while working on the transmitter. I will likely abandon this idea and look into using it as intended at a future date.

That's it for now.

_______________________

May 8, 2022

The SB-401 rebuild has been halted with no idea when I will start it up again. I'm kind of in a daze and shock. I wanted to get my Dad's SB-401 transmitter going again. I have the other station pieces he never had but wanted. I was building that set up using his gear and adding my own so that he could one day operate the dream system he never got to. Now that won't happen. At approximately 0215 EDT this morning, my Dad, W4KIS (formerly KF4VI)- James Emery Nash, Jr has gone SK. May he have the time of his life up there doing the things he wanted but couldn't.

____________________________

Comments

Post a Comment